Fault diagnosis in machine tools using selective regional correlation

September 1, 2011

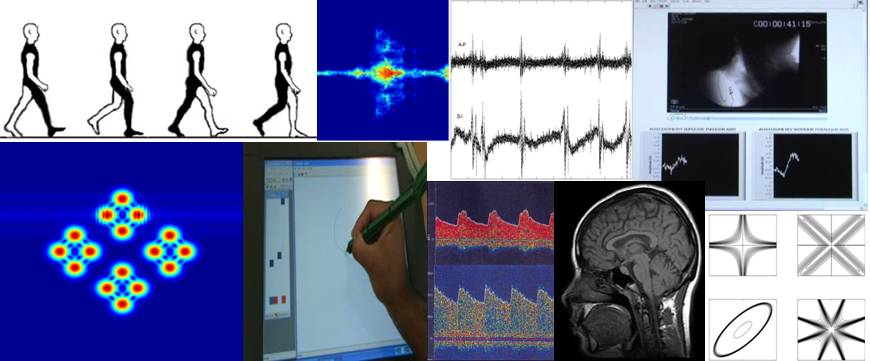

This paper investigates the detection and diagnosis of brush seizing faults in the spindle positioning servo drive of a high-precision machining centre using a recently developed time–frequency pattern classification technique known as selective regional correlation (SRC). It is shown that SRC is capable of significantly enhancing the resolution of fault diagnosis when compared to conventional correlation-based techniques. The performance of this approach is evaluated using three time–frequency transformation techniques: the short-time Fourier transform (STFT), continuous wavelet transform (CWT) and S-Transform. In addition, three different 2D windows are used to isolate features for use with SRC: a rectangular (boxcar) window, a Gaussian window and a Kaiser window. The results have indicated that SRC is a promising tool for machine condition monitoring (MCM).

This material is presented to ensure timely dissemination of scholarly and technical work. Copyright and all rights therein are retained by authors or by other copyright holders. All persons copying this information are expected to adhere to the terms and constraints invoked by each author’s copyright. In most cases, these works may not be reposted without the explicit permission of the copyright holder.